Page 2 of 2

Posted: Mon Feb 20, 2012 12:52 am

by yorklyn

I say, what ever system you have in place now that is OEM, keep it that way unless you're willing to consult someone who knows this stuff, it can get complicated and dangerous if not done right.

I totally agree! when we first bought the boat the bonding wires were a mess. I told my marina to "sort them out and make them right" . They charged me over $500 (7yrs ago) and did nothing but crimp ends on 5 or 6 wires! nothing was connected to anything else! most wires were simply laying unconnected in the bilge! since I never had enough of the origional system in place im alittle lost on how to fix it. I lost faith in profesional help (for the most part) long ago after experiencing the same thing over and over again. I have found that asking questions in a forum such as this to be 1000x more informative and helpfull than paying a marina to send a $10hr guy who knows next to nothing to work on my boat! (sorry for my rant but thinking back to the first time I saw the "repair" the marina did on my bonding system got me going"!!

Posted: Mon Feb 20, 2012 4:59 am

by alexander38

we understand, that's why I've learned has much as I have. The throwing of money down a hole doesn't sit well with me, most marine mech's sux. I've seen a couple of good ones but for the most part not....

Posted: Mon Feb 20, 2012 9:57 am

by Big D

A good marine tech is worth thier wieght in gold. When you find one, you keep him close. Keep in mind though that even the best with mechanical experience may not be completely familiar with some electrical systems. Look for one with an electrical ABYC or equivilent designation. Remember that even the pros are devided on some electrical issues so it's an example of how complicated it can get on a boat, and thus be beyond the abilities of some techs. The best advice is for you the consumer to do exactly what you're doing now....your homework.

Posted: Mon Feb 20, 2012 12:14 pm

by gettaway

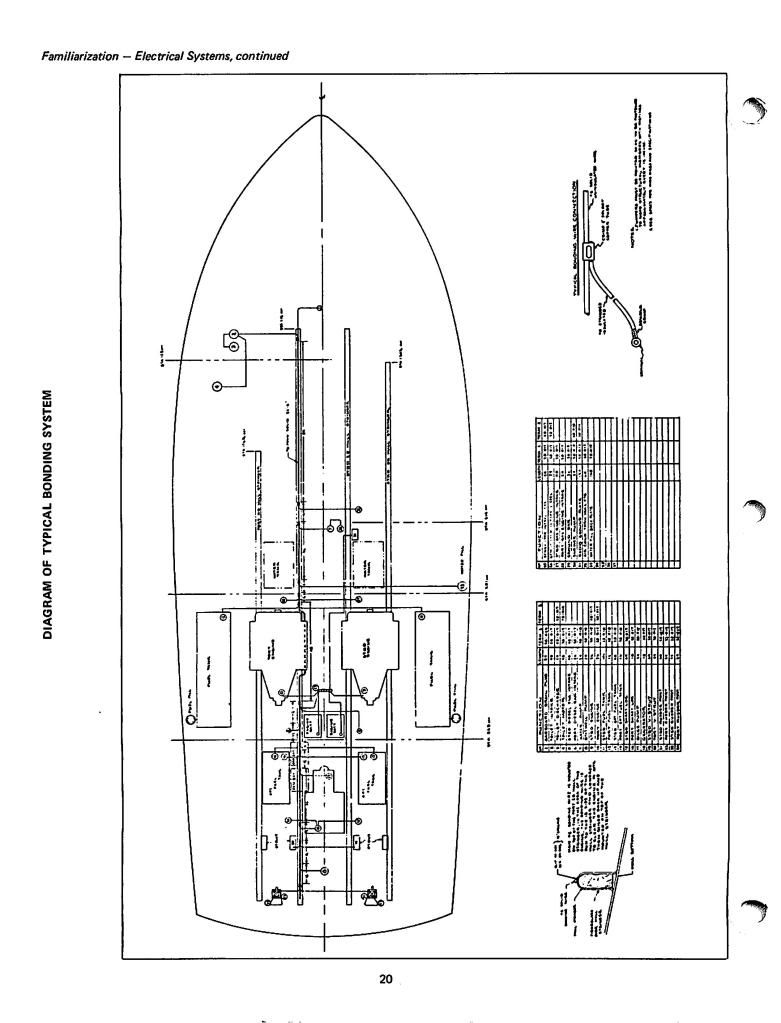

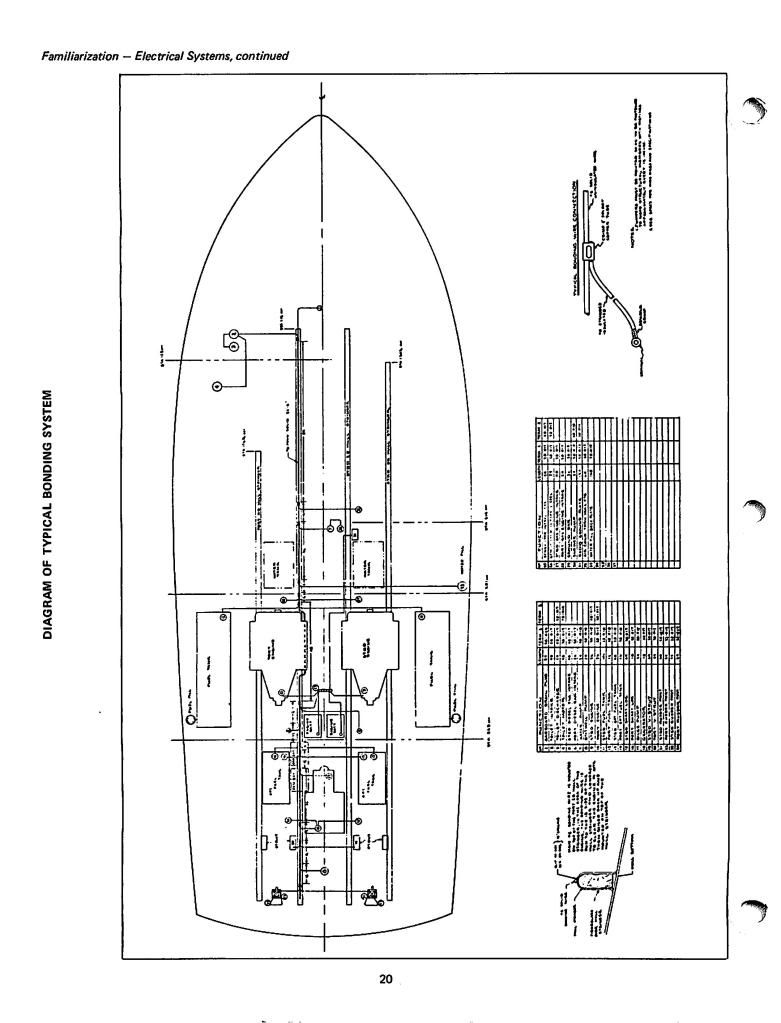

I would follow the original bonding system , I have the original bonding system schematic for a 1977 F-32 if you need it.

if you are having electrolisys problems, make sure your wiring connections are good and you are changing your anodes frequently enough.

Posted: Mon Feb 20, 2012 10:31 pm

by yorklyn

gettaway,

I would love to see that schematic. do you think you could scan and post it?

Thanks alot

Posted: Tue Feb 21, 2012 12:15 am

by gettaway

Ill try to get it scanned tomorrow and will pist it as soon as possible

Posted: Tue Feb 21, 2012 4:54 am

by alexander38

gettaway wrote:I would follow the original bonding system , I have the original bonding system schematic for a 1977 F-32 if you need it.

if you are having electrolisys problems, make sure your wiring connections are good and you are changing your anodes frequently enough.

and if you are find the reason why..

Posted: Tue Feb 21, 2012 9:25 am

by larryeddington

Marine tech's outside of our sponsors, I have not found one. Everytime I use one I am left with something half done and not a happy camper.

That is why I have been my best tech in virtually all things mechanical and electrical. IMO anyone can learn what is necessary by investing a little time and planning and you then have the best tech, who loves ya.

Posted: Tue Feb 21, 2012 9:26 am

by larryeddington

Marine tech's outside of our sponsors, I have not found one. Everytime I use one I am left with something half done and not a happy camper.

That is why I have been my best tech in virtually all things mechanical and electrical. IMO anyone can learn what is necessary by investing a little time and planning and you then have the best tech, who loves ya, yourself.

Posted: Wed Feb 22, 2012 10:01 am

by gettaway

This is what is in my owners manual, it is under "familiarization"

it is not anymore legible in the manual

Posted: Wed Feb 22, 2012 6:17 pm

by yorklyn

Thank You so much!!!

Posted: Wed Feb 22, 2012 7:32 pm

by koviak

Most corrosion of zincs and underwater metals occur from the A/C voltage side. These are often grounded to the bonding system on boats. And when docked with other boats that are also on shore power the boats become a path for grounding stray currents. The easiest way to avoid problems is with the installation of a galvanic isolater. These units use diodes to only allow current flow in (1) direction so corrosion issues are eleminated. My marina was very bad (change zincs 2x a summer). Put in the isolater last spring and zincs are still in one piece in the fall. Figured since your fixing bonds my be something to look at.

Posted: Wed Feb 22, 2012 7:34 pm

by yorklyn

Thanks, I remember reading about that in one of books. Sounds like it would a wise choice.

Posted: Wed Feb 22, 2012 9:32 pm

by Big D

I agree galvanic isolators are good to have. Be carefull with the installation and follow the instructions closely. Where the gound connection on the vessel is made is critical; do not connect the device in the AC to DC bonding conductor. You should also check with state by-laws. In some juristictions, it is a violation to insert any device into a main grounding (safety) conductor, and the use of an isolator will violate such, thus invalidate an insurance policy. You should also keep in mind that the isolator does nothing to protect against corrosion from a DC leak on board such as bilge pump wires lying in bilge water that is in contact with any hardware that goes through the hull. Only adequate anode protection will help you there so keep an eye on them and the wiring in your bilge.