Page 7 of 13

Posted: Wed Apr 27, 2011 7:37 pm

by larryeddington

Remember you have to deal with thrust I started a string on this a while back ad there was a lot of coment

Posted: Wed Apr 27, 2011 7:45 pm

by pk

Yes Larryeddington. But thrust do we have already, I mean the propeller shaft must be fixed to the gearbox in one way or another. And the connetions is fixed only with two small set-screws in the flage and into the shaft. The only thing is you have to make the propeller shaft 2 1/2 inch shorter. Another thing is you dont pick up more torque sideways (radial movement) if you use yokes. At least as far as I understand.

Posted: Wed Apr 27, 2011 7:52 pm

by larryeddington

I agreejust putting out there some of the ressponsess I got. In my opinion. The yokes can take thrust. I will bet there will be disagreement. Hope you are correect

Posted: Wed Apr 27, 2011 7:54 pm

by pk

If not, I will not be angry. Thats the way we learn....

Posted: Wed Apr 27, 2011 7:57 pm

by captainmaniac

Just think about the load and pressure on it... Moving a car or light truck through air versus moving 20,000 pounds of boat through constant resistance of water... you will be putting WAY more load on the drive parts than a regular vehicle would. Just make sure you end up with something reliable enough that you can actually enjoy the boat (in other words, don't do something that's just gonna go SNAP the first time you hit the throttle - you have put too much blood, sweat, other body parts, and money into her to not be able to enjoy her).

Posted: Wed Apr 27, 2011 8:03 pm

by pk

Blood.... Tears... I will be careful. Take it nice and easy.... But now my queen the Fury called me from the bedroom.... Time is 02:08, or middle of the night. And she feels a bit lonly up there....

Lucky me! Good night all!

Posted: Wed Apr 27, 2011 8:11 pm

by RWS

uh......

It would be really BAD if the shaft slipped out and the boat filled up with water.

Seriously, there is a reason for those couplers.

Better be careful here and don't try to re-invent the wheel.

RWS

Posted: Wed Apr 27, 2011 10:21 pm

by wowzer52

Check with boat builders/engineers before using splines. Stuffing boxes and fiberglass cannot take even a few thousands out which automotive splines have all the time. Do more research. Like was mentioned, There is a reason for couplers. cracking out the fiberglass around the stuffing box would sink your boat instantly. You have put too much time and money into your boat to skrimp now and possibly loose your boat. We care about you.

Posted: Thu Apr 28, 2011 5:33 am

by pk

Goooodmmooorrrningg to ya all!!!

A new day has arrived, with new possibilities and new gifts! I had read your words, and contacted a company who deals with shaft-joints and yokes. With splines or members. They have asked me to carry on with the work, just to see the results. Well, I have the two shafts here, with splines. And I have two more shafts witout splines. And I have a pair of coupler flanges with flex-dish to put in between. Both for members. They will be fixed to the shaft with each two set-screws, secured with ,11 locking aircraft type wire. Maybe it is better to do it this way. Too many of you guys eager me to lay down the spline-work.

And as some of you say: Not fun to find the boat filled with the soup we like to travell around in.

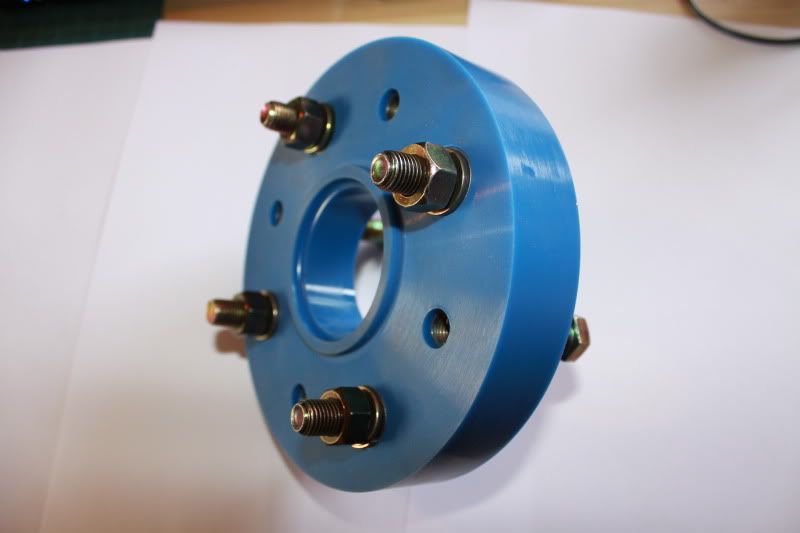

Here is one of the flanges......

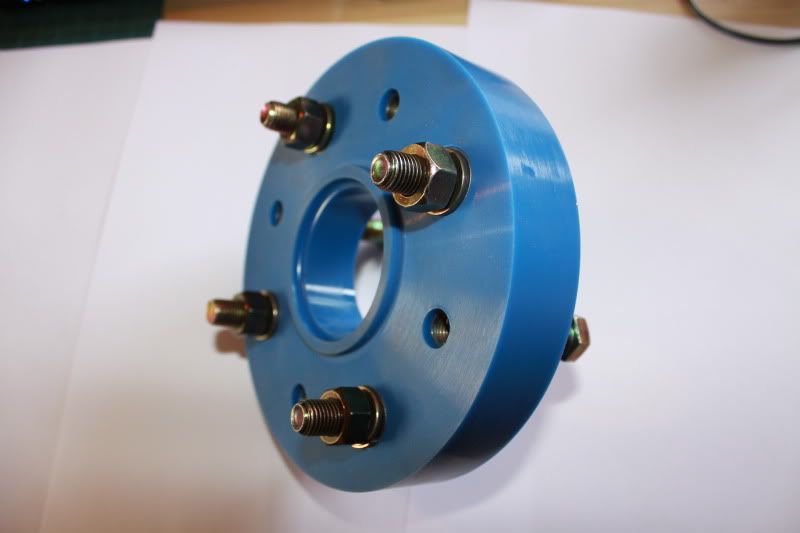

...and the Flex-Dish.

Posted: Thu Apr 28, 2011 7:11 am

by prowlersfish

The reason they use splines in the auto/truck world is so the drive shaft can move in and out of the gear box . as the suspension moves up and down. there is no real push pull loading on the shaft .

on a boat all the force of moving the boat is push on that shaft . the shaft stays in place and a thrust bearing in the gear box takes the load and keeps the shaft in place . is you had splines the shaft would move forward instead of moving the boat . until it bottomed out in the splines or the prop hit the strut, not good . in reverse the prop of course would hit the rudder . the only way to stop that would be to put a thrust bearing on the shaft . and if you do that why have splines ?

in other words keep it simple like the boat came , and you know it will work .

Posted: Thu Apr 28, 2011 10:36 am

by plansea

I am certainaly no expert, but me thinks that if there was a better way the large manufacturers and suppliers would be using it. If it ain't broke, don't fix it ! Respectfully Larry

Posted: Thu Apr 28, 2011 2:18 pm

by Stripermann2

The prop has to remain stationary! Besides what Paul has outlined, the momentum and speed of the prop, in a stationary axias is just one component of thrust. Alter this and you will no longer have consistant and equal thrust. Especially between two engines.

Also, any component you add to a drivetrain which moves or twists, absorbs some of the torque applied to the prop, hence less end torque.

When you have a solid shaft applying torque directly, this is best.

I think if engineers thought a slip yoke set-up on a straight drive was a good idea on a marine application, every boat would have them.

Posted: Thu Apr 28, 2011 3:12 pm

by pk

OK!! OK!!! I understand! I will put in the "normal" shaft, no spline, and no yoke. But I will put in this Flexi-Disk..... OK?

Posted: Thu Apr 28, 2011 3:27 pm

by Stripermann2

pk wrote:OK!! OK!!! I understand! I will put in the "normal" shaft, no spline, and no yoke. But I will put in this Flexi-Disk..... OK?

Just trying to help you prevent headaches down the road...

The flex disc will be fine.

Posted: Thu Apr 28, 2011 4:01 pm

by pk

Thank you Jamie! And for the rest of you: I am very thankful for all good advice. Even if I´m not follows them all..... Sometimes I´ll have to test things out for my own sake.

I am an old, stubborn, Norwegian. Sorry!